MB W113 / 560SL

Mercedes 230SL with 560SL drivetrain

This job was one of the most complex projects accomplished so far. It was performed for a customer in Tennessee, USA who bought on an auction a Mercedes W113 230SL with an un-concluded 560SL engine transplant.

As always, this kind of purchases at places like that bring a lot of surprises behind.

The owner contacted us via the sl113.org forum, were many members recommended people to go with specific experts in order to have such a project finished in the right way.

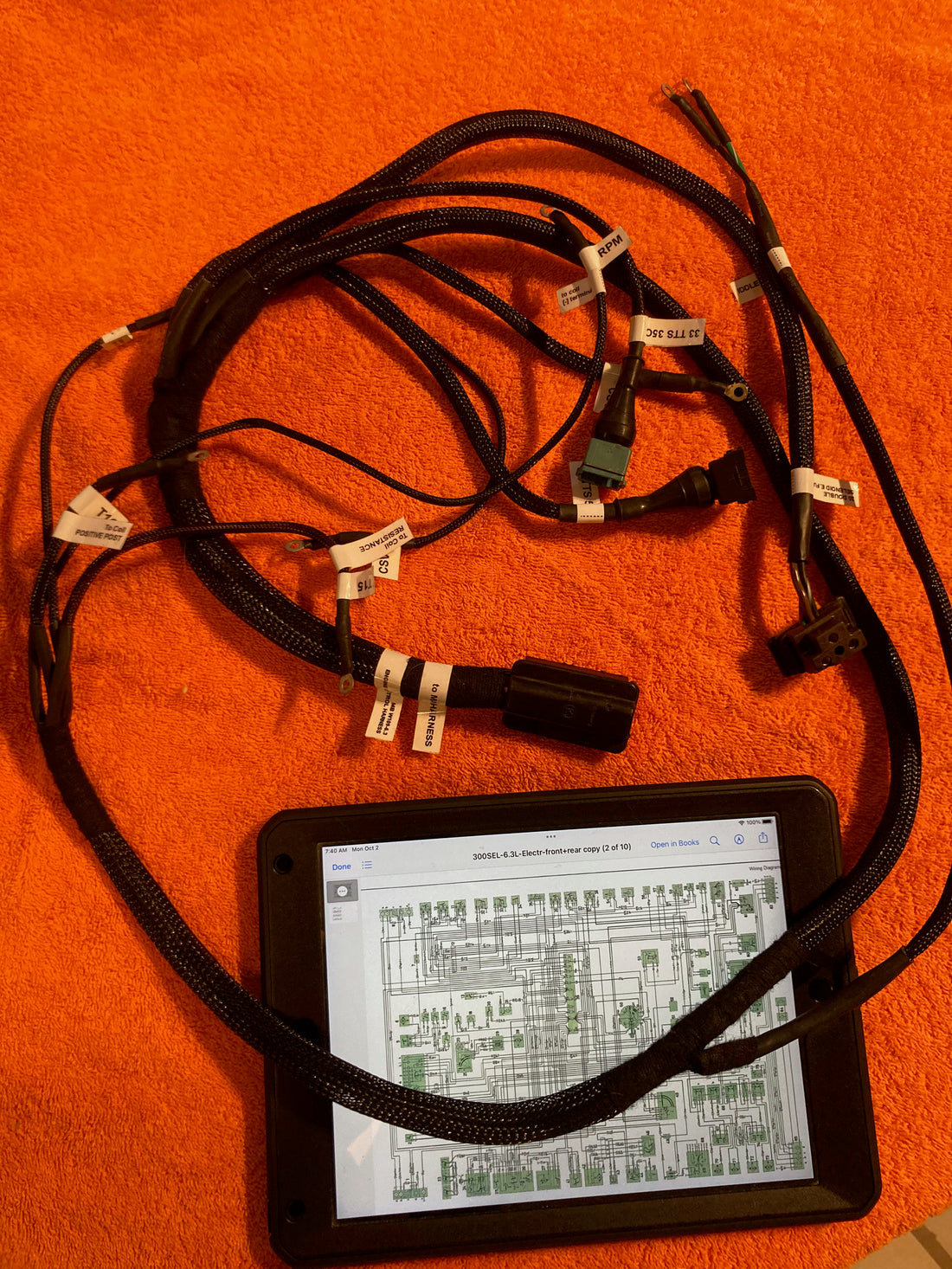

Well, this job took us about a month to resolve all the problems and required the total modification of the W113 main harness to be able to work with the 560SL engine/transmission control harnesses. All this was done in the cleanest and most professional way.

In general terms this were the modifications made:

- Increase of charging capacity. All T30 circuits were enlarged and main ignition switch was changed towards a later style 280SL plug style tumbler.

- Interconnection between legacy harness to new ones. 560SL drivetrain needs certain signals and power from the original W113-230SL, and for that purpose two new branches were created to fullfil the function of ports named X49/2 and port X26 described on 560SL ETM manual.

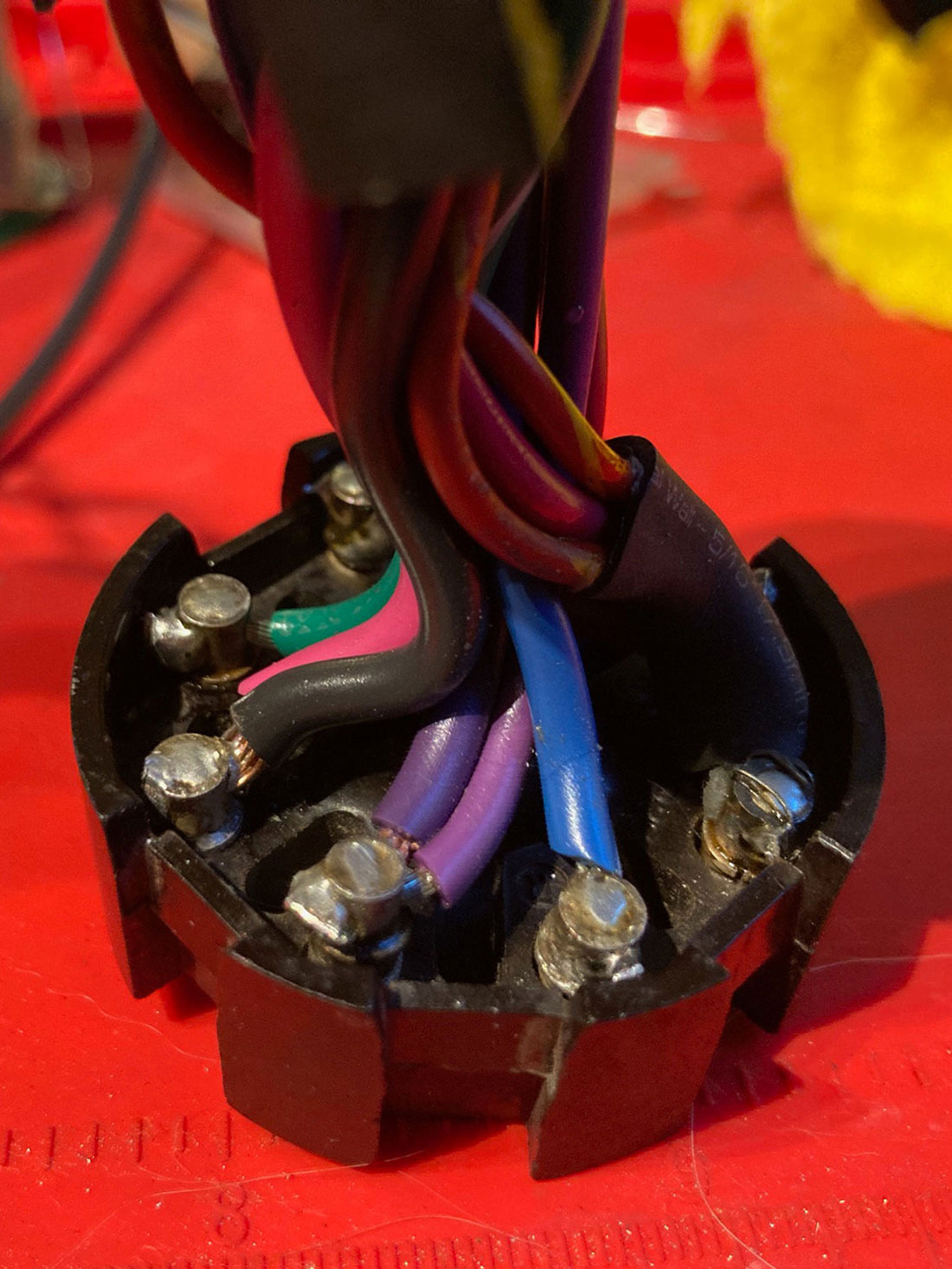

- Signal conversion. The AC current speed signal coming from 560SL transmission harness needed to be converted into a digital one as needed by KE Jetronic ECU, that required a lot of investigation but goal was reached.

- Instrumentation. The modern drivetrain from the 560SL needed to change the arrangement of the temperature gauge and tachometer. For that purpose later 280SL electrical driven gauges for those functions were installed. The needed signals were brought to the instrumentation panels via re-maping of the main 12 pin connector.

- Fuel pump. KEjetronic has full control over the pump, as a result all circuitry from original harness was remade to make this possible.

- A/C provisions. All the changes were made on the main 113 harness to handle an aftermarket AC system.

- Radiator cooling. Because of space limitations a standard radiator fan clutch arrangement was not possible. Therefore provision for a pair of radiator fans were made, triggering them with fixed temperature and AC refrigerant gas pressure values.

Many other modifications were made which surpass the scope of these description. The important thing here is that a project that appeared to be impossible was completed with success….

Here some project photos: